TRITIUM - Tritium Transport and Process

Last Releases

4.1.3, January 2024

4.1.2, January 2022

4.1.1, May 2020

4.1.0, March 2019

User Cases

Status

Commercial toolkit, available for sale and project development

Applications

Simulation of processes involving hydrogen isotopes

- Transient analysis of the tritium inventory in fluids and materials: concentration of tritium at different process locations.

- Transient analysis of the tritium permeation between fluids through the containing material and to the room where the system is located.

- Support of decision-taking for process engineering.

- Support with deciding on the materials to be used.

- Analysis of tritium transfer surface phenomena.

- Dynamic analysis of tritium inventory under conditions of no tritium generation.

- Modeling of different scenarios of pulsed generation of tritium.

- Simulation of changes in the composition of the process fluid.

Description

Fusion power is based on the fusion of deuterium with tritium creating He-4 and releasing a significant amount of energy. Special attention must be paid to the production systems, the test blanket modules (TBM) and Breeding Blankets (BB), coupled to their auxiliary recovery systems.

EAI, in collaboration with Fusion Spanish Lab (CIEMAT), has developed toolkit for the simulation of systems and processes involving hydrogen isotopes for the study of transport phenomena focused in controlling their inventory and permeation.

The phenomena included in the TRITIUM toolkit are:

- Available species include hydrogen isotopes (H, T, D) and their homonuclear(Q2) and heteronuclear molecules (HT, HD…), as well as polyatomic molecules by combination in diatomic and water (Q2O) molecules.

- Tritium generation: different profiles and pulsed generation scenarios

- 1D diffusion model in materials (LiPb, Eurofer, AISI 316L, etc)

- Co-diffusion and co-permeation of hydrogen isotopes in the TBS sub-systems and components

- Sievert’s equilibrium between different materials

- 1D piping for the circulation of liquid and for gases

- Chemical reactions when Q2 and Q2O species are present

- Surface phenomena calculated in the material surface in contact with gas. The models can also be run imposing a diffusion limited regime.

- Trapping considered in the materials with configurable trap types and characteristics.

Large set of available materials with their transport properties (difusion coefficient, Sievert’s constant, recombination and dissociation coefficients) and possibility to work with user defined materials.

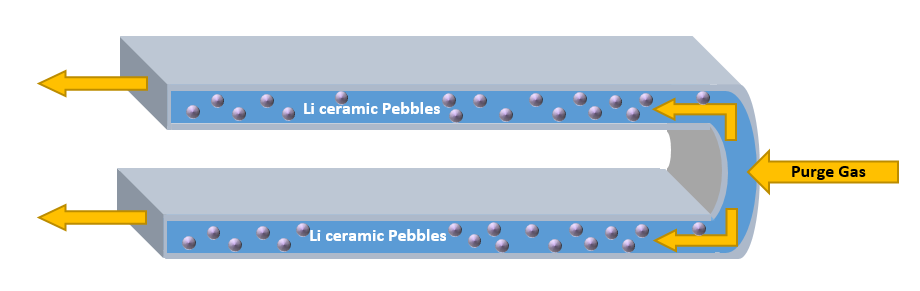

Tritium Generation in a Solid Breeder

This model represents a tritium solid breeder: tritium is generated in a pebble bed of lithium ceramics located in two channels. A helium flow, called purge gas, is introduced through these channels so the released tritium is dragged by it. The selected material for the helium channels is Eurofer. The system is all at the same temperature.

The aim of this example is to analyse the tritium permeation through the material and the inventory in the different parts of the system.

The model is built with two fluid channels connected to the materials that represent their walls and the pebble component representing the lithium ceramic. Both channels have the same geometry and operation conditions.

The realease of tritium from the lithium ceramic breeder is set through the residence time and HT/(HTO+HT) ratio.

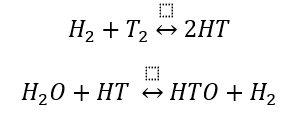

Inside the gas pipes, two reactions will be considered:

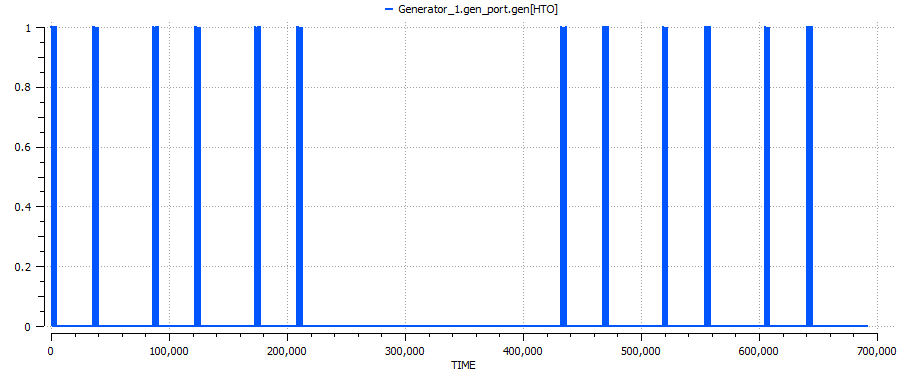

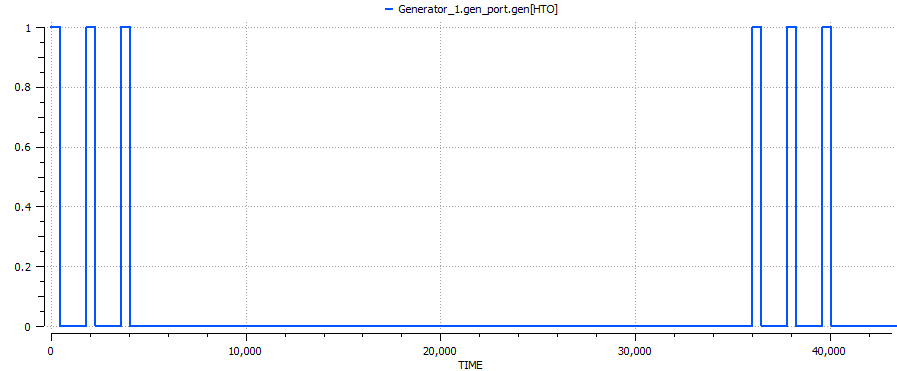

The generation profile is defined in the Generator component: it will consists on three pulses. Each pulse will be 450 s of burn and 1350 s of dwell. The second group of pulses starts 10 h after the first, and this generation is repeated with a period of 1 day. This generation profile lasts three days (generation time) and then the generation is turn off during 2 days. That means a generation cycle (time between two on generation cycles) equal to 5 days. These generation pulses are shown in the plot:

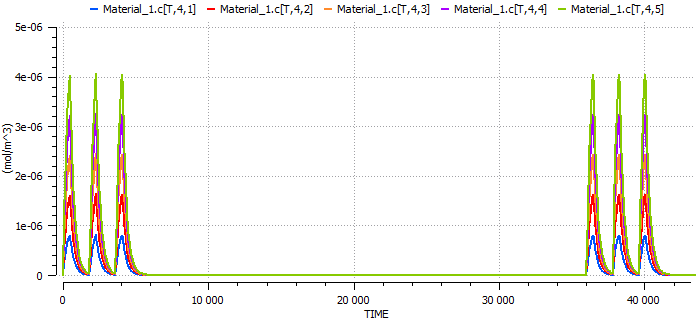

Zooming in the first 43200 s (1/2 day), the three generation pulses are observed:

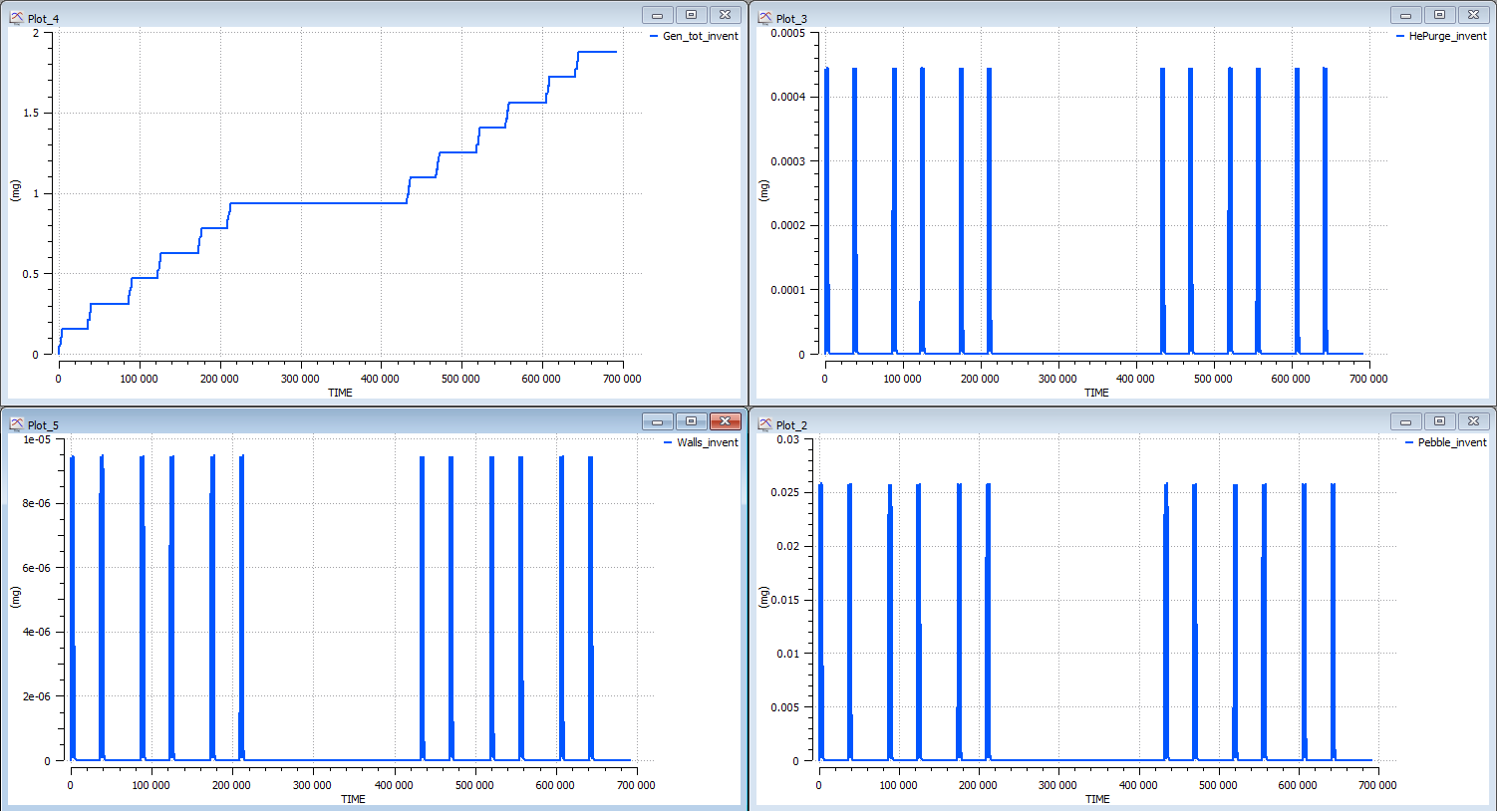

The evolution of the inventory in each elemnt of the model is shown in the plots below for a 10 days simulated time.

The plot “Gen_tot_invent” represents the amount of tritium generated inside the pebbles. It can be observed that it remains constant when the generation is null. The tritium inventory in the pebbles is also pulsed according to the pulsed generation. The maximum amount of tritium inside the pebble during the pulses is around 0.026 mg and it falls to zero when there is no generation.

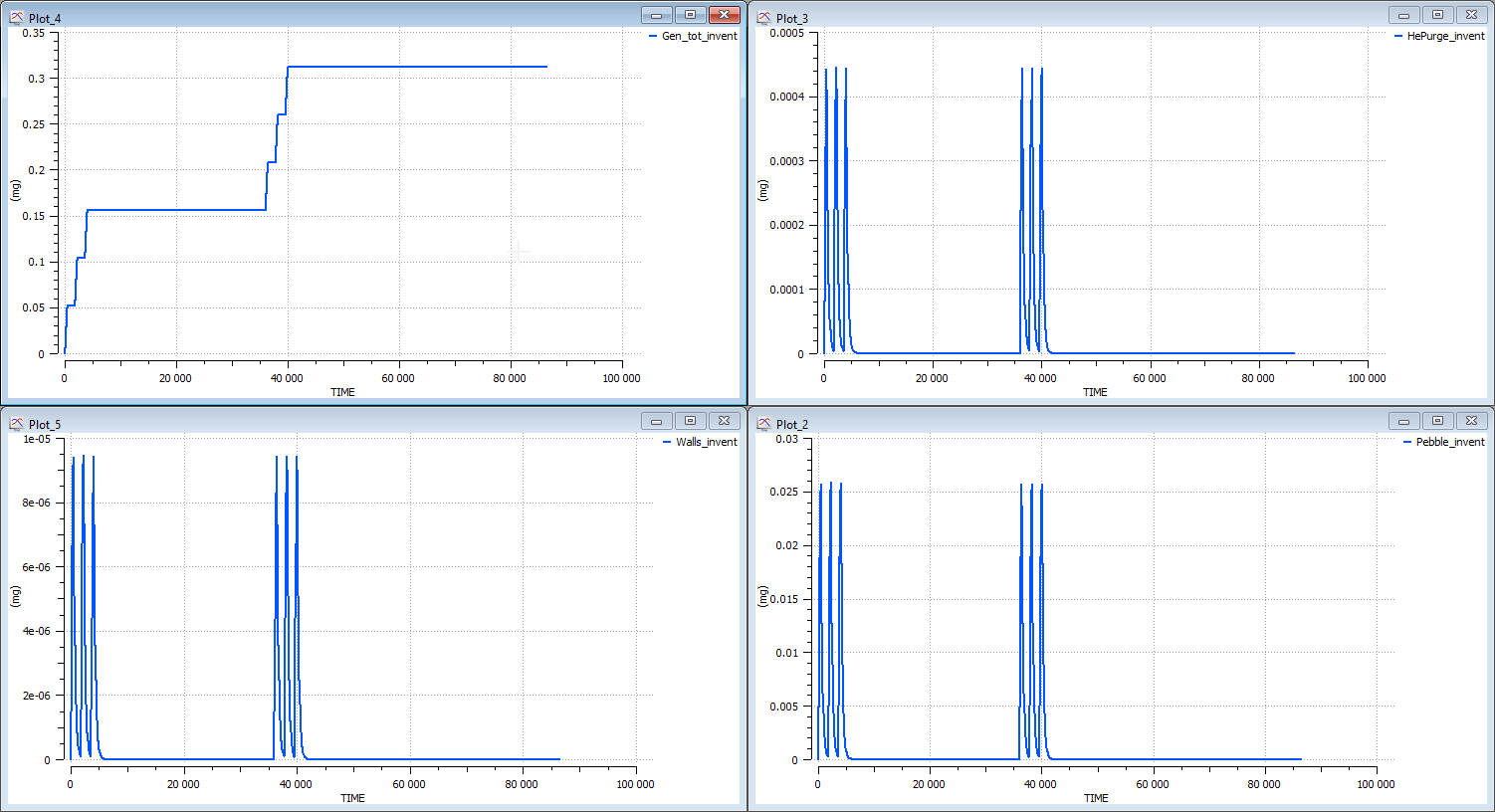

Again, zooming in the previous plots the first day (or simulate the experiment with TSTOP = 86400 s):

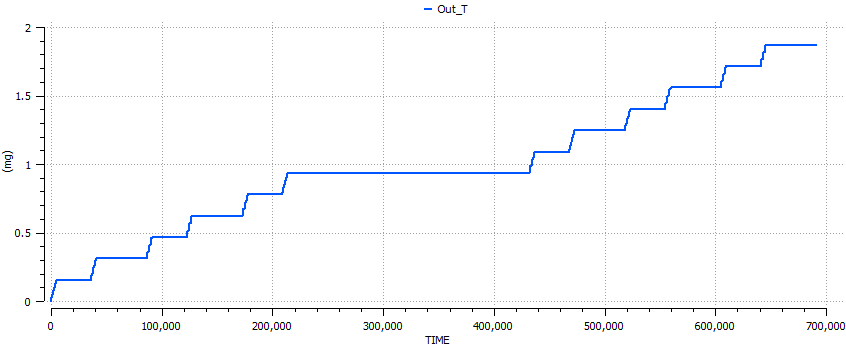

The tritium inventories in the purge gas and the walls have the same behaviour, but the maximum value in the pulses in much lower. That means that most of the tritium generated leaves with the purge gas stream as it can be checked in the next plot:

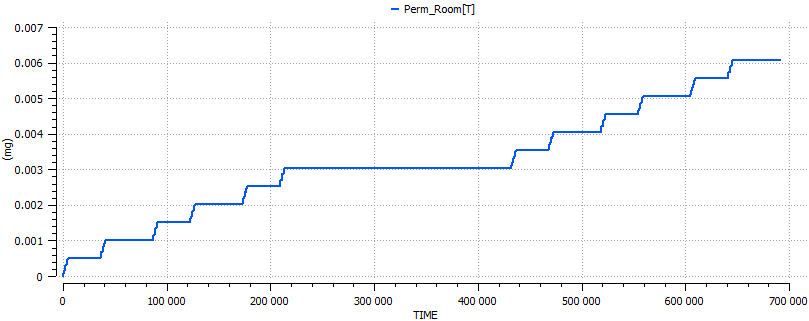

The tritium permeated through the wall increases with the generation pulses and remains constant when there is no generation.

The tritium concentration in the outer face of the material along the gas flow direction during the first half-day is represented in the next plot. It can be observed that it is higher as we move towards the gas outlet.

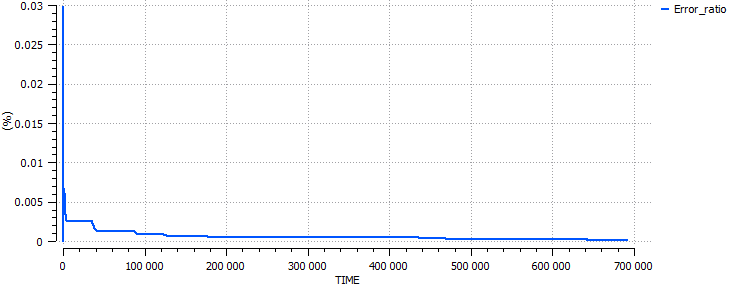

Finally, the relative error at the beginning reaches 0.03%, but it decreases until practically zero which means the mass balance is correct.